产 品 展 示

PRODUCTS

Provide customers with low-priced professional ore products and high-quality and efficient services

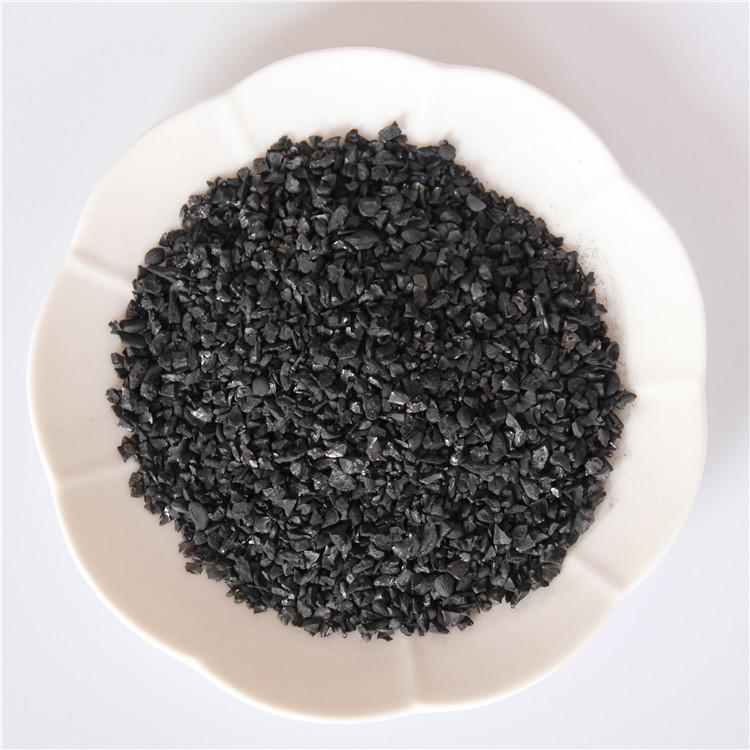

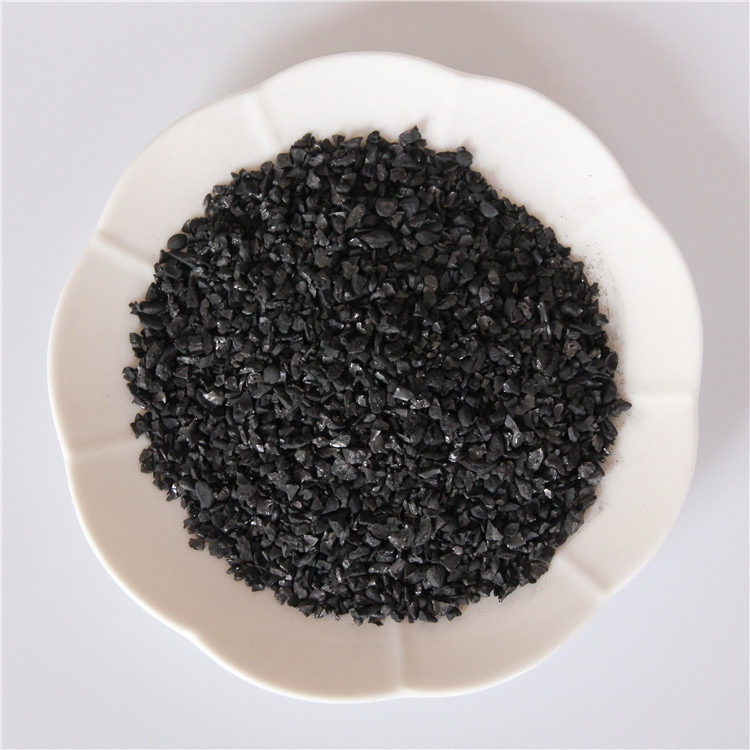

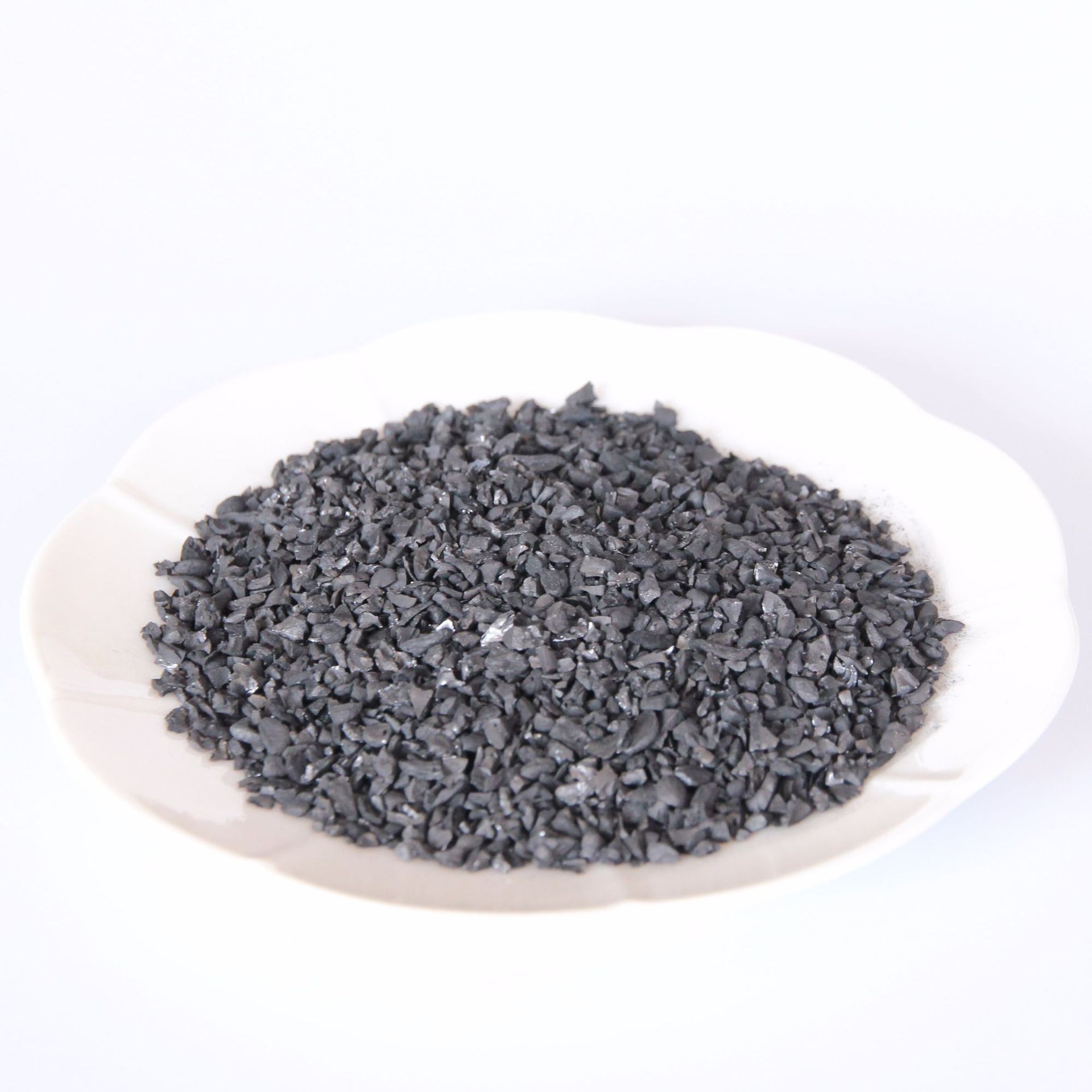

Activated carbon is a type of carbon that has been specially treated by heating organic materials (such as fruit shells, coal, wood, etc.) under isolated air conditions to reduce non carbon components (this process is called carbonization), and then reacting with gas to corrode the surface and produce a structure with well-developed micropores (this process is called activation). Due to the fact that the activation process is a microscopic process, where a large amount of molecular carbides corrode the surface in a point like manner, numerous small pores are formed on the surface of activated carbon. In theory, the diameter of micropores on the surface of activated carbon is mostly between 2-50nm. Even a small amount of activated carbon has a huge surface area, with a surface area of about 500-1500m2 per gram of activated carbon. In theory, almost all applications of activated carbon are based on this characteristic of activated carbon. The carbon content, specific surface area, ash content, and pH value of the aqueous suspension of activated carbon all increase with the increase of activation temperature. The higher the activation temperature, the more complete the volatilization of residual volatile substances, the more developed the microporous structure, and the larger the specific surface area and adsorption activity. The ash composition and content in activated carbon have a significant impact on its adsorption activity. Ash content is mainly composed of K2O, Na2O, CaO, MgO, Fe2O3, Al2O3, P2O5, SO3, Cl -, etc. The ash content is related to the raw materials used to produce activated carbon, and increases with the removal of volatile compounds in the carbon.

上一个: -

下一个: -